Hot Search:

| Picture | Product name | Product parameters |

|

SWINGWAXINGMACHINE | The swing waxing machine fully combines the circulation structure and swing structure.This series of equipment can process 600-2200mm sized stone with yellow feet,and fill the pores on the polished sur- face with nano liquid to achieve anti fouling and brightening effects.Grinding head components do not require special lubrication,have minimal damage,stable structure,good rigidity:the whole machine has a high degree of standardization,easy operation,stable and reliable work,low maintenance costs:intelli- gence:human-machine interface,easy and convenient operation,quantifying all operating parameters |

|

SWING ANGLE POLISHING MACHINE | Swing angle polishing machine is an improved polishing machine that has been upgraded from the conventional pol- ishing machine in the ceramicindustry to address the large grinding volume in the stone industry.The new polishing ma- chine has upgraded the grinding head,lifting components,and fixed simple structure to better meet the requirements of stone polishing,equipped with an infinite grinding and polishing machine,it achieves high-quality production through connected production.Intelligence:human-machine interface,simple and convenient operation,quantify the stability of all operating parameters:Combining years of production experience in polishing machines,solidifying excellent systems, and upgrading specific systems.Low noise:Upgrade specific systems to greatly reduce the noise generated by grinding blocks and surface grinding. |

|

NON-POLAR POLISHINGMACHINE | The infinite grinding polishing machine is a new type of polishing machine developed for surface pol- ishing products such as stone that require large cutting amounts.It effectively meets the requirements of high output and low energy consumption.At present,it can meet the production requirements of various specifications such as 600-2200mm. |

|

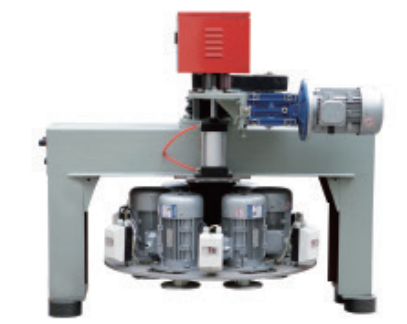

CIRCULATION GRINDING POLISHINGMACHINE | The circulating polishing machine is a series of products developed based on the characteristics of glazed tiles.Unique and effi- cient automatic copying planetary mechanism grinding disc,equipped with super wear-resis- tant and sharp grinding tools,specialized for polishing glazed tiles;The surface gloss after polishing.Thoroughly solved a series of prob- lems in the current glazing process,such as grinding tool intolerance up to 80°,easy scratching,bottom penetration,missed pol- ishing,and high equipment costs. |

|

CIRCULATION GRINDING WAXPOLISHINGMACHINE | The circulating polishing and waxing machine is a specialized equipment designed for anti-stain and brightening treatment of tiles and stone surfaces.It repairs surface pores and micro-cracks,ensur- ing exceptional stain resistance and uniform gloss.This series can process products ranging from 300 to 2200mm in size.When combined with nano-liquid polishing,it fills surface pores and repairs micro-cracks,achieving superior stain resistance and consistent luster.Key structural features include:the wear-resistant grinding head requires no dedicated lubrication,offers excellent stability and rigidity; |

|

Table With ElevitorFor 5-layer Dryer | |

|

Single Layer | |

|

Tile Body Scrap Machine | This machine is to brush off the tile surface defect such as dust and burrs to make the tile surface be smooth.the machine be equipted with high quality flat belt and high-strenth glass to ensure the tile tobe conveyed stably and reliably.Being made of high quality and high-density cloth,the brush rubs the tile in an efficent andgentle way.This machine is sepecialy suitable for the fragile thin tile. |

|

Press Take Off Table | This equipment cleans the bricks pressed by the press and then flips them or directly to the equipment in the next process.This equipment uses the rod with good rigidity and high straightness to make the roller rod run more smoothly.Own to aluminum alloy profile is used to install the roller rod part,the equipment is lighter.With highquality timing belt is used on the transmission,the equipment runs with low noise. |

|

Belt Balance And Slip Stirrer | Round Sieve:To screening the powder or slurry |

|

Vibrating Sieve | Round Sieve:To screening the powder or slurry |

|

Hydraulic Coupling |